Trends in Mechanical Engineering

Jun 01, 2018

Modern society is changing and mechanical engineering degrees are evolving along with it. Gone are the days of massive steel monsters belching smoke and steam. We have entered the age of efficient, smart products with highly integrated functions, often miniaturized to the point where we do not even notice them anymore. Smartphones are a great example. They provide our news, weather, and communications, and much of our entertainment. Normally thought of as electronic marvels, most people miss the mechanical sophistication and elegance of the design. Mechanical engineering trends can be divided into three major areas: improvements to the product development process, improvements to the product manufacturing process and making products more robust.

The product development process is responding to the demands of consumers for increased functionality, better reliability and faster introduction cycles. Mechanical engineering increasingly relies on leveraging proven, existing technology, while weaving in new technology in an ordered process that reduces time to market and mitigates risk of failure due to technological issues. Additional features typically include increased connectivity and embedded processors expanding functionality. Digitization of the entire documentation chain eliminates transcription and translation errors and reduces tooling time and costs. It also enables mechanical simulations with increasing sophistication where much of the product design validation is via simulation rather than expensive and lengthy product testing.

New materials are also challenging our concepts of what is possible. For example, high-resolution smart phone screens are made of Gorilla Glass. They far exceed the physical toughness of glass that was available just a few years ago. Without it, our phones would be much larger and heavier, and the screen would likely not be so vibrant and detailed. Similarly, new car engines and components have reduced vehicle weight, improving gas mileage without sacrificing performance or safety. Finally, sub-systems and components are upgraded continually, increasing the efficiency and performance of batteries, magnets, motors and engines.

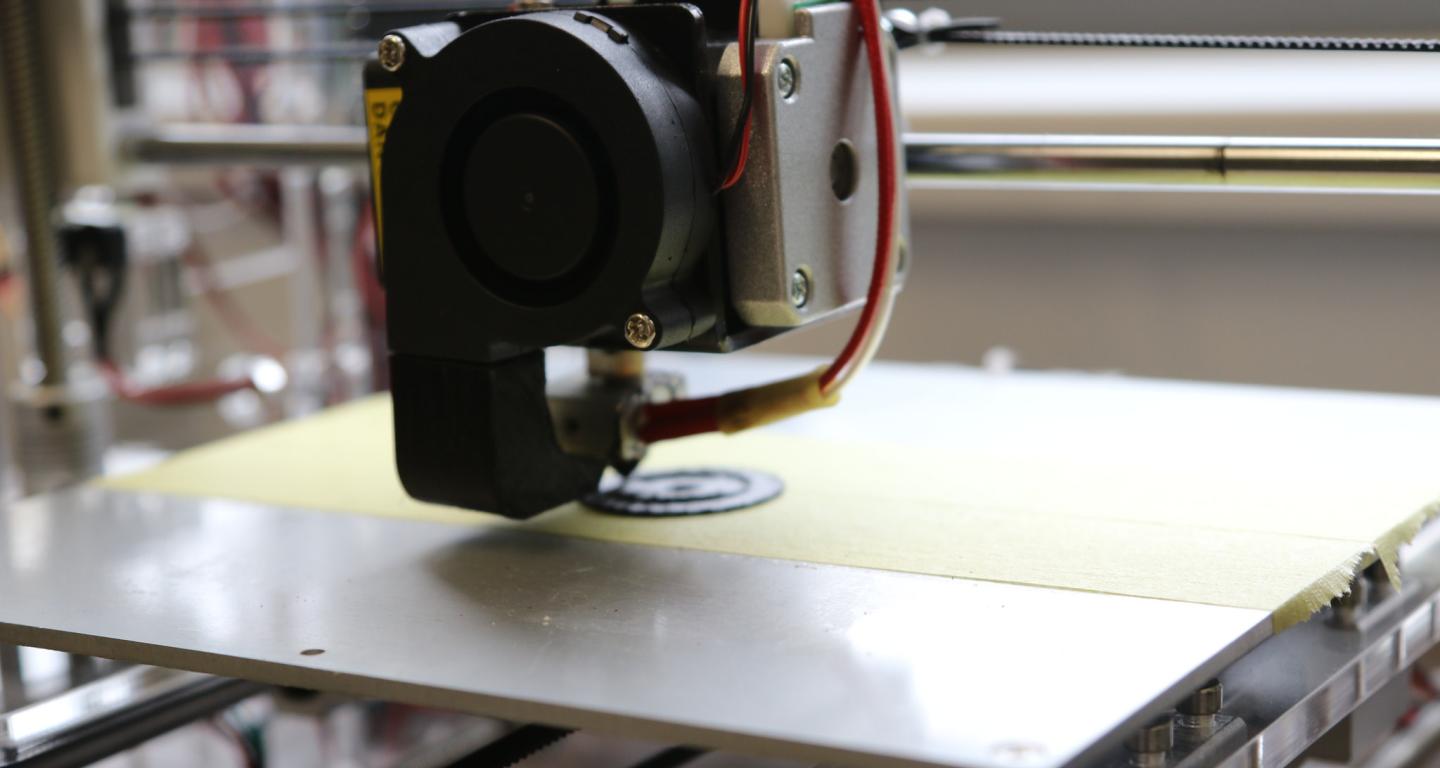

Manufacturing processes are evolving as well. Additional automation speeds manufacturing rates while simultaneously reducing product failures and scrap. Products are designed to be made in local factories throughout the world, using generally available materials. Customization is a growing trend where the manufacturing process is so flexible that products can be made to order with minimal lead times.

Consumers expect high levels of product quality and performance. Often this means embedded processors and sensors must be used in conjunction with predictive software to alert the consumer to potential failures, allowing them to either service or replace the item before catastrophe strikes. Reliability is also enhanced by modifying product functionality under marginal operating conditions.

Mechanical engineering is evolving rapidly on many fronts, from design sophistication via increasing reliance on computer modeling, to manufacturing automation and improved materials, to ever-increasing quality driven by embedded processing and sensor technology. Mechanical engineering is keeping pace with the progress of the 21st century, and when it’s enriched with a strong core of liberal arts learning, like in the engineering programs at North Central College, it allows us to create more innovative solutions to better society.

About the author:

Frank Harwath spent over three decades working in industry designing and developing products and processes. As an entrepreneur, he started three companies and ran an independent consulting firm for 13 years. Throughout his career he has accumulated 87 patents and designed products used in high performance computers, graphics hardware, cell phones, fiber optics, and sporting goods.